|

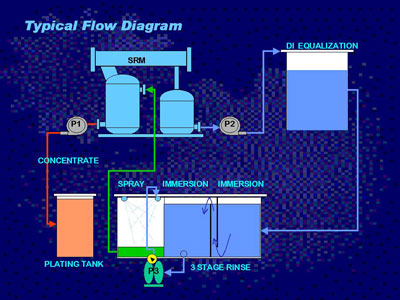

In the typical

metal finishing operation, as much as much as 90% of the finishing solution is

lost during the rinse process. The resulting wastewater represents not only a

reduction in profit, it also represents a real environmental issue that invites

scrutiny from city, county, and state environmental agencies. La Habra

Welding has the answer the Solution

Recovery Master (SRM).

The SRM

offers a unique concept that recovers spent plating solutions or chemicals from

rinse water. The recovered solution is concentrated in the SRM unit

and because the process has no effect on the basic chemistry of the solution it

can be potentially recycled. An added benefit of the SRM is

that it generates D.I. water, which can be reused in rinse

operations. Regardless, the SRM reduces the load on conventional

treatment systems, which represents a substantial savings in chemical

costs.

After the work

leaves the metal finishing solution it is spray rinse and immersed through a

double counter flow rinse water system to ensure through rinsing (note that the

rinse operation utilizes primarily recycled D.I. water). Wastewater, collected

from the spray rinse process is monitored by the SRM programmable logic

controller (PLC). When the PLC determines that a specific amount of wastewater

has been collected for processing, the Solution Recovery Master initiates its

process automatically, requiring no operator intervention. After the process is

complete the SRM PLC transfers the D.I. water to a holding tank that feeds the

rinse water system. Solution concentrate is stored in the SRM until the operator

initiates a transfer. It is important to know that that the low processing

temperature utilized during this operation ensures that the basic

chemistry of the solution is not affected, and also minimizes the energy

required to operate the SRM.

Lets talk about how the Solution

Recovery Master can help your operation.

11/10/06 12:58 PM

|